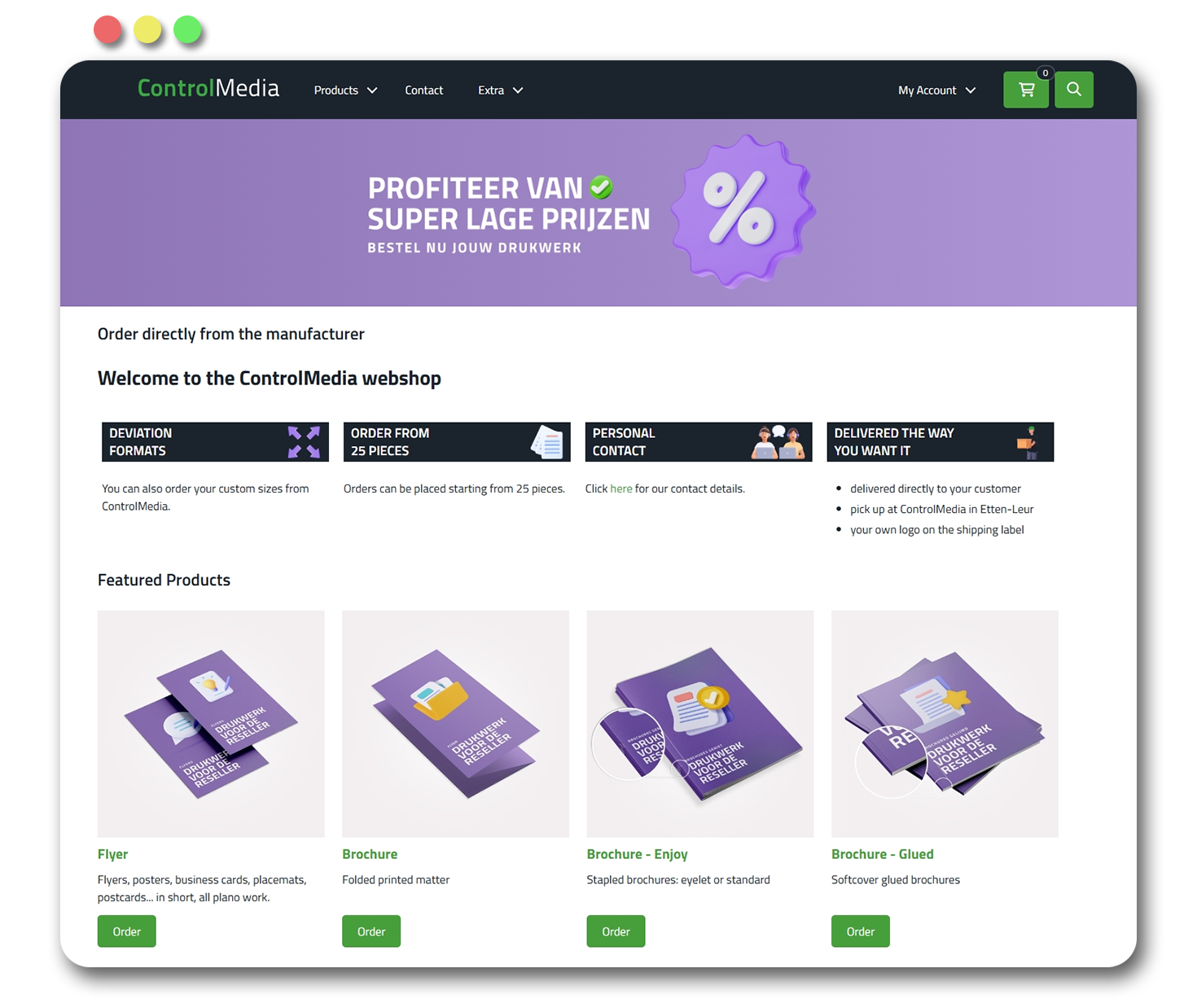

Deep Integration with Production Workflows

Control Media’s investment in workflow automation paid off significantly. With Infigo’s open architecture, Boris connected automated file checks, routing, and production triggers directly into the platform through integrations like Enfocus Switch, effectively turning the webshop into an intelligent, end-to-end production system.

The integration goes much deeper than simply passing files to the press. Infigo’s platform orchestrates Control Media’s entire production workflow. When an order arrives from the webshop, it automatically performs preflight checks, validates file specifications against production requirements, and flags potential issues before they reach the production floor. The system routes jobs to the appropriate equipment based on substrate, size, and finishing requirements, and even manages colour profiles and imposition layouts specific to each press.

“The platform doesn’t just move files – it makes decisions,” Boris explains. “It’s checking bleeds, resolving colour spaces, optimizing imposition, and routing work to the right press at the right time. What used to require multiple touchpoints and manual intervention now happens automatically, even at 2 AM when no one’s in the office.”

The connected system also handles split-shipping logic, coordinating when different components of a single order need to be produced on different equipment or at different times, then ensuring everything syncs correctly for delivery. For Control Media’s 24/7 operation, this level of automation transformed what was possible during overnight production runs.